BÜTFERING Schleiftechnik GmbH

Formerly great German manufacturer of widebelt sanding machines and technology located in Beckum

Longyear member of the HOMAG Group

The BÜTFERING-technology has been integrated in the HOMAG machines of the SANDTEQ W series since 2018.

Selected series and products

FBS

Until around the mid-1980s

AF2/AF3 and UF2/UF3

Constant table-sanding machines 'heavy type' (until approx. end of 1980s); AF - sanding from top; UF - bottom sanding

Lacquer sanding and polish sanding machines

Between 1985-1994 (approx.) very often produced series

UWS

Bottom sanding (in connection with AWS models for use in sanding lines)

ECO and Classic

Successor of the AWS series, approx. in 1994

Compact entry-level machines for crafts and interior design companies

Mid-range construction series starts in midst 1990s .

Heavy, individual equipment series, production approx. in 1993 until 1997

E-Line

Approx. in 1996

PRO

Series in collaboration with Sicar , approx. in 1998

Solid wood machines (early 21st century)

SBC, SKO and STO

Successor models of Eco-and Classic machines

Entry-level model with height-adjustable table and 1-4 units, working width 1100/ 1350mm

SKO

Machines including a constant table height, electronic pad, feed frequency-and-belt speed, etc.

Machines with up to 4 aggregates Special models:

- Sandy: starter model, 1-2 aggregates

- Special: equipment for veneer/ lacquer, a combination aggregate with CPS technology

- Lucky: 2 aggregates with CPS technology

- Diamond: special models of the SCO-series, up to 4 aggregates

- M-SCO: with cutterblock and additional 1-2 sanding aggregates

SBO

For example SBO 109 - sanding width 950mm, 1 combination aggregate (2005)

Designed for solid wood sanding

SVR

SGO

1-3 aggregates machines with 1-2 contact rollers and electronic segmented pressure pad, variable feed speed, automatic thickness adjustment (2007)

SCR

SBR

Machines for brushing and structuring functions (approx. in 2005 until 2007)

Series since approx. 2009

- SWT 100 : starter models with 1-3 aggregates

- SWT 300 : Modular design for versatile applications

- SWT 500 Diamond: high-tech equipment with 1-4 aggregates

- ProfiLine SWT 700 / SWB 700 series with up to 5 aggregates

- PowerLine SWT 900: up to 7 aggregates, especially for industrial use

Additional designations and their meaning

| R | Contact roller unit (approx. until 1994, Bütfering used the letter K for this aggregate-type) |

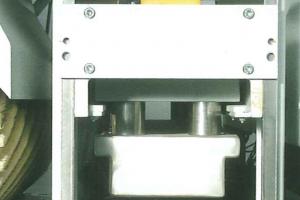

| C | (C)ombi-aggregate (contact roller-sanding pad-aggregate) |

| L | Combi unit (contact roller workpiece controlled air pad (series Super) |

| K | Combi unit with profiled contact roller 65° and pneumatic sanding pad (SWT100-2009 series) |

| E | Sanding pad unit with electronically controlled segmented pressure bar - also as a combined unit |

| Q | Cross sanding unit |

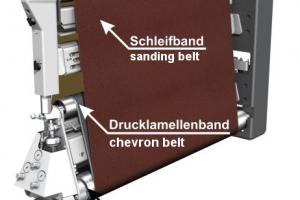

| H | Aggregate with electronic pressure beam and inside running pressure segment belt - Super-finishing aggregate |

| T | Plate brush aggregate |

| B | Brush unit (roller brush over entire working width) |

| M | Cutterblock |

History

| 2017 | With the slogan 'One company - one brand' changed HOMAG their marketing strategy. In the future the panel sizing saws by HOLZMA, the edge bending machines by BRANDT and the CNC-machines by WEEKE of the grinding machines by BÜTFERING all carry the HOMAG-logo. |

| 2012 | Since 1st October, BÜTFERING Schleiftechnik GmbH and WEEKE Bokhrsysteme GmbH have been united. BÜTFERING is now a trade mark for innovative sanding Technology, incorporated in WEEKE Bohrsysteme GmbH. |

| 2012 | The metal sanding machine division of Bütfering is sold to Lissmac Maschinenbau GmbH. Lissmac produces in Beckum, which is also the location of its service and exhibition centre for nothern Germany and the Benelux countries. Bütfering's sanding machine division and many workers move to the Weeke location in Herzebrock-Clarholz. |

| 2010 | 18 distributors, more than 60 distributors worldwide, one of the largest manufacturer of wide belt sanders for every application |

| 2006 | Antonius Bütfering gives up his responsibilities to Michael Mracharcz. |

| 2005 | Presentation of series SCR |

| 2002 | Accession to the HOMAG Group |

| 1998 | Establishment of a production facility in northern China and 2003 in Shanghai |

| 1996 | Formation of the metal grinding field 'Steelmaster' and 'Europe Award' for the development of electronic segmented pressure bar; 50th anniversary |

| 1995 | ISO 9001 certificate for quality assurance |

| 1990s | Expansion of market position |

| 1989 | Franz Bütfering dies. Antonius and Franz-Josef Bütfering are appointed to the management. |

| 1989 | Development of the electronically controlled segmented pressure bar for the crafts. It was followed by the series AWS; machine: AWS-E, which revolutionized the surface technology in crafts (1990: Federal Innovation Award 'by the German Ministry for this development) |

| 1984 | Awarding of the 'Bavarian State Prize' |

| 1960s/70s | Exports to more than 100 countries and increase of the production capacity |

| 1960s | Entry into the wide belt-technology and final specialization on production of bottom sanding machines (series:FBS) . |

| 1958 | Second plant in Sendenhorst |

| After World War II | Enormous demand for wood processing machines: production of chain-milling-machines, special mitre cut saws, veneer presses and Spitzenköpfmaschinen (tree top cutting machines) for grinding, buffing of high-gloss polyester finishes. Processing machines of veneer and painted surfaces was the main production area of BÜTFERING. Band sanders (especially Model C 55) are considered as pioneers in the development of wide belt sanders. |

| 15.03.1946 | Founded by the brothers Franz and Anton Bütfering as Gebrüder BÜTFERING Maschinenfabrik |

show full history