Ligne de production de meubles de corps BIESSE 2 x Winner, 2x Stream, 2x Techno

| Fabricant | BIESSE |

| Sous-catégorie de machines | Ligne de production de meubles de corps |

| Année de construction | 2014 |

| N° d'article | 95890 |

| Endroit | ex emplacement |

| Disponibilité | court-terme |

| État de fonctionnement | encore utilisé(e) dans la production |

avancement maximal en | 40 m/min |

avance réglable sans paliers | |

marque CE |

Double strand feeding system WINNER C 3200

Dimension elements:

max length 3200 mm

min length 300

max width 1200 mm or 2x 600 mm per roller conveyor

40 m/min Feeding speed

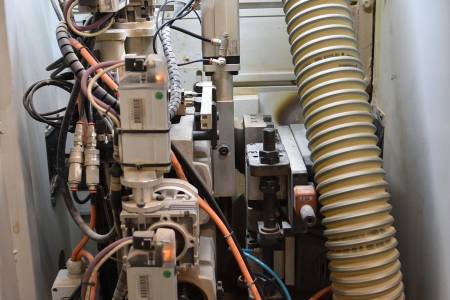

Double-sided edge banding machine BIESSE SB1/7.5

30 m/min using corner copying/moulding unit + profile scraper unit

40 m/min for ABS-PVC-PP in longitudinal run

50 m/min with thin edge in longitudinal run without WINNER infeed

Double hogger DT 10 2x 8.1 kW

Universal milling unit FS 30 1x 5.8 kW

Glue application unit SP 30 incl. EVA premelter 16 kg/h + PURBlue PUR premelter 20 kg/h

when using PUR - exchange SP 30 and using application nozzle NORDSON EB 60

Flush milling unit RS 10 2x 2 kW

Multi-profile fine milling unit RF 40 2x 1 kW (chamfer + 3 profiles) including HIGH SPEED KIT

Universal milling unit FB 30 1x 5 kW

Multi-profile scraper unit RB 40 (chamfer + 3 profiles) including HIGH SPEED KIT

Flat scraper unit RC 20

Buffing unit SZ 30

Turning device BIESSE GPK-1

Double-sided edge banding machine BIESSE SB2/10.5

Dimension elements:

max length 2700 mm

min length 240 mm

max width 1200 mm

min width 240 mm

rolling chain with cams (Cam spacing 500 mm)

automatic centre support

double hogger DT 10 with protection cutter AS 10 2x 8,1 kW + 1x 5,8 kW

Pre milling unit RT 20 2x 3,5 kW

glue application unit SP 30 incl. EVA premelter 16 kg/h + PURBlue PUR premelter 20 kg/h

when using PUR - exchange SP 30 and using application nozzle NORDSON EB 60

Cross-cut saw unit IT 90X (3 pneumatically adjustable positions)

Flush milling unit RS 10 2x 2 kW

Multi-profile fine trimming unit RF 40 2x 1 kW (chamfer + 3 profiles) including HIGH SPEED KIT

Corner copying/mould milling unit AR 80 2x 0.65 kW HIGH SPPED KIT 30 m/min and quick-change tool heads

Multi-profile scraper unit RB 40 (chamfer + 3 profiles) including HIGH SPEED KIT

Flat scraper unit RC 20

Buffing unit SZ 30

NC-controlled dowel and hole line drilling machine BIESSE Techno FDT

NC-controlled dowel and hole boring machine BIESSE Techno F

Turning device BIESSE GPK-2

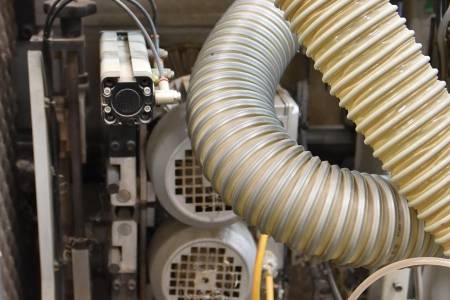

Cleaning system WANDRES Ingromat, top and bottom

Double strand destacking system WINNER SC 3200

Dimension of processed elements:

max length 3200 mm

min length 300

max width 1200 mm or 2x 600 mm per roller conveyor

min width 200 mm

Software line monitoring: SUPERVISOR